FR4101 Cleanroom Booth

Products

Products DETAILS

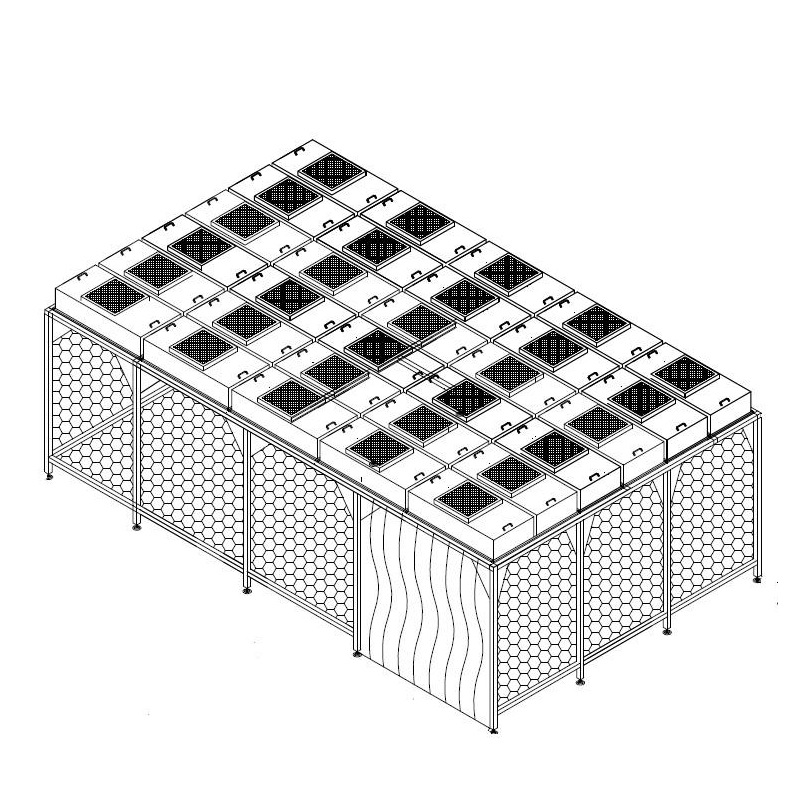

FR4101 Cleanroom Booth

Cleanroom Booth – Description

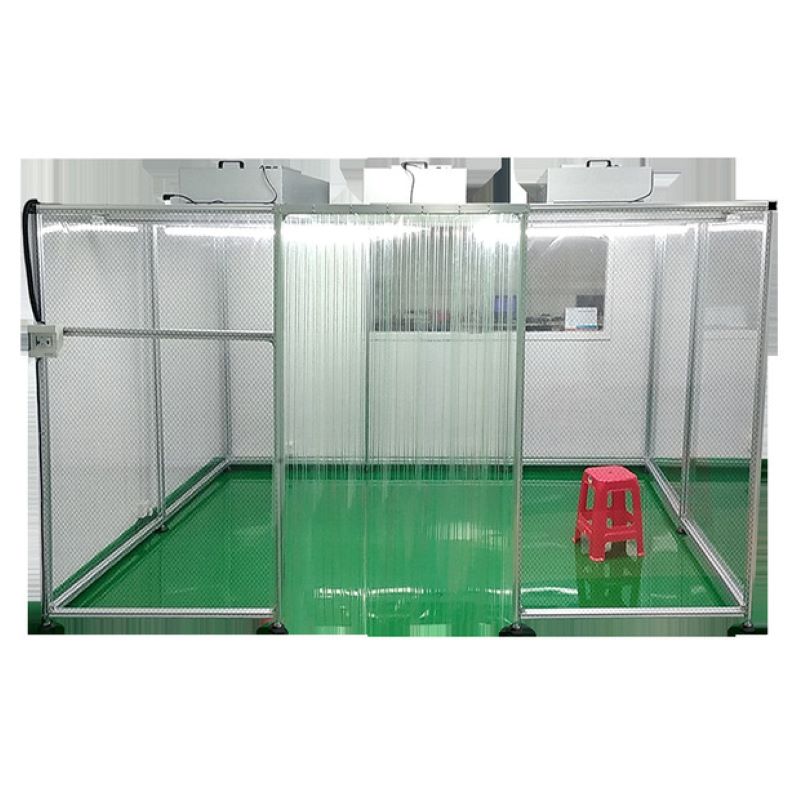

A Cleanroom Booth (also known as a Modular Cleanroom Booth or Clean Booth) is a self-contained, modular enclosure designed to provide a localized clean environment within a larger uncontrolled or semi-controlled space. These booths use HEPA or ULPA-filtered airflow systems to maintain particle-free zones and meet various cleanroom classifications according to ISO 14644-1 or GMP standards.

Cleanroom booths are a flexible and cost-effective solution for industries such as pharmaceuticals, microelectronics, biotechnology, aerospace, medical device manufacturing, and laboratories.

Key Features

-

HEPA/ULPA Filtration: High-efficiency filters mounted in the ceiling provide unidirectional (laminar) or turbulent airflow, ensuring Class 100 to Class 100,000 clean conditions (ISO Class 5 to 8).

-

Modular Construction: Made from aluminum, powder-coated steel, or stainless steel frames with clear PVC, acrylic, or polycarbonate side panels.

-

Self-Contained Design: Allows installation without major structural changes; ideal for creating clean zones within existing facilities.

-

Fan Filter Units (FFUs): Integrated into the ceiling to continuously supply clean, filtered air.

-

Lighting & Electrical Provisions: LED lighting and optional power outlets are available.

-

Casters or Fixed Legs: Some models are mobile for flexible positioning, while others are stationary.

Benefits

-

Cost-Effective: Less expensive than full-scale cleanrooms, with reduced construction and operational costs.

-

Scalable & Customizable: Easily expandable or reconfigurable based on changing needs.

-

Quick Installation: Minimal downtime or disruption to existing operations.

-

Localized Clean Environment: Ideal for sensitive processes like inspection, packaging, or assembly in otherwise non-classified areas.

-

Compliance Support: Helps meet cleanroom standards (ISO, GMP, FDA) without a full cleanroom infrastructure.

Applications

-

Precision assembly and inspection

-

Clean storage and packaging

-

Pharmaceutical filling and sampling

-

R&D and laboratory operations

-

Semiconductor and microelectronics handling

-

Medical device manufacturing