FR3501 Cleanroom Air Shower

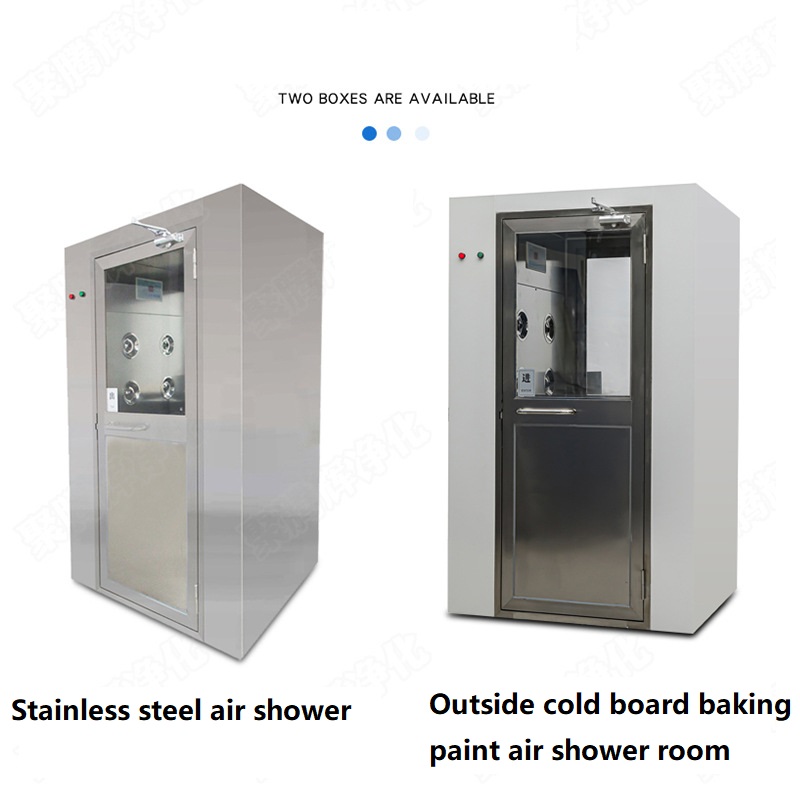

1. Material : Stainless Steel Air Shower/Outside cold board baking paint air shower room

2. Style : Double Blows for 1 person / Double Blows for 2 person / Double Blows for mutiple person

3. External Size : 1240*1000*2100mm / 1240*2000*2100mm / 1240*3000*2100mm

4. Internal Size : 790*860*1930mm / 790*1860*1930mm / 790*2860*1930mm

5. Cleanliness : [email protected]

6. Air Speed : 13-25m/s

7. Nozzle QTY : 12/24/36

8. Shower Time : 0.99s adjustable (exfactory settings 10s)

9. Fan power : 380V50HZ

10. Fan power supply : 1500W 1unit/ 1500W 2unit / 1500W 3unit

11. Control Method : Voice prompt blowing shower, electronic interlock, photoelectric induction

12. High efficient filter and primary filter: 1 piece each / 2 piece each / 3 piece each

13. Configuration : LCD display screen,emergency button,door closer can be choose

Products

Products DETAILS

FR3501 Cleanroom Air Shower

Cleanroom Air Shower – Description

A Cleanroom Air Shower is a specialized enclosed chamber installed at the entrance of a cleanroom or controlled environment. It is designed to remove surface particles from personnel or materials before they enter the clean area, thereby reducing the risk of contamination. Air showers use high-velocity, filtered air jets to blow off dust, fibers, and other particles from clothing or equipment surfaces.

Air showers act as a decontamination portal between classified and non-classified areas and are widely used in pharmaceuticals, biotechnology, semiconductor manufacturing, aerospace, and food processing industries.

How It Works

-

The user enters the air shower through the entry door, which then locks automatically.

-

High-speed jets of HEPA-filtered air (typically around 20–30 meters per second) are blown through nozzles to dislodge and remove contaminants.

-

The air is recirculated through pre-filters and HEPA filters to maintain efficiency.

-

After the cycle (usually 15–30 seconds), the exit door unlocks, allowing entry into the cleanroom.

Key Features

-

HEPA or ULPA Filtration: Removes 99.97% of particles ≥0.3 microns (HEPA) or 99.9995% of particles ≥0.12 microns (ULPA).

-

High-Velocity Nozzles: Strategically placed nozzles provide uniform decontamination across the body or equipment.

-

Interlocking Doors: Prevent both doors from opening simultaneously to maintain pressure and cleanliness.

-

Stainless Steel or Powder-Coated Construction: Ensures durability, cleanability, and corrosion resistance.

-

Programmable Control System: Allows users to adjust shower duration, cycle delay, and filter status monitoring.

-

Lighting and Indicators: Includes interior lighting, visual/audible indicators, and emergency stop buttons for safety.

Benefits

-

Reduces contamination risk from personnel or materials entering cleanrooms.

-

Supports compliance with ISO and GMP cleanroom standards.

-

Improves cleanroom efficiency by maintaining cleanliness classification.

-

Easy to integrate with cleanroom entry protocols.

Applications

-

Pharmaceutical manufacturing

-

Semiconductor and microelectronics industries

-

Aerospace component assembly

-

Biotech and research laboratories

-

Food and beverage processing plants

-

Hospitals and sterile processing departments