FR3203 Cleanroom FFU

Products

Products DETAILS

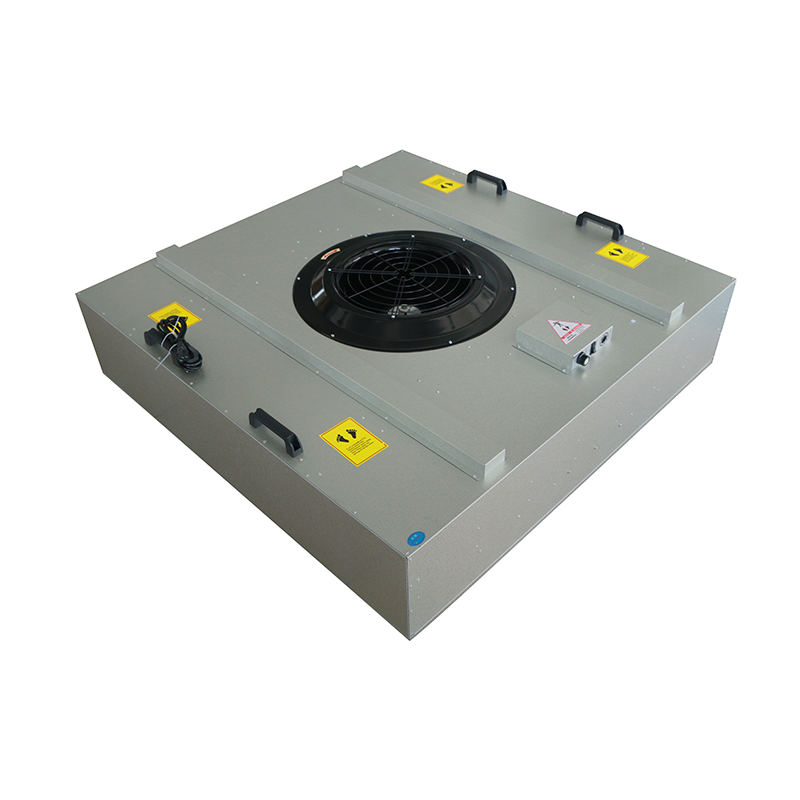

FR3203 Cleanroom FFU

Fan Filter Unit (FFU) – Detailed Description

A Fan Filter Unit is a self-contained air filtration system designed to supply clean, particle-free air in controlled environments such as cleanrooms, laboratories, and medical or manufacturing facilities. It combines a motorized fan and a high-efficiency filter into a single compact unit, typically installed in the ceiling grid of cleanroom spaces.

The FFU draws in ambient air from the plenum or external space above the ceiling, forces it through a HEPA or ULPA filter, and then delivers clean air in a uniform, laminar flow downward into the controlled space. This continuous supply of filtered air helps maintain the required air cleanliness levels by removing airborne particles and contaminants.

Main Components

-

Housing or Casing: Constructed from materials like stainless steel, aluminum, or coated steel to ensure durability and resistance to corrosion.

-

Fan and Motor: A built-in low-noise fan ensures a steady and adjustable airflow.

-

HEPA or ULPA Filter: These filters trap microscopic particles and are chosen based on the cleanliness level required. HEPA filters remove at least 99.97 percent of particles 0.3 microns or larger, while ULPA filters remove at least 99.9995 percent of particles as small as 0.12 microns.

-

Air Distribution Panel or Grille: Provides a uniform flow of clean air into the room.

-

Control Options: May include manual or electronic controls to adjust fan speed, monitor filter status, or connect to building management systems.

Typical Features and Specifications

-

Airflow capacity generally ranges between 500 and 1000 cubic feet per minute

-

Filter options include HEPA (high-efficiency particulate air) or ULPA (ultra-low penetration air)

-

Noise levels are typically kept below 60 decibels for quiet operation

-

Power options vary and are customizable depending on regional standards

-

Common unit sizes include two feet by two feet and two feet by four feet, though custom sizes are available

Applications

-

Cleanrooms across various ISO classes

-

Semiconductor and electronics manufacturing

-

Pharmaceutical production environments

-

Aerospace and defense assembly areas

-

Food and beverage processing facilities

-

Healthcare spaces such as hospital operating rooms and labs

Advantages

-

Provides consistent, high-quality clean air

-

Modular and scalable design makes it easy to expand or modify systems

-

Energy-efficient options help reduce operational costs

-

Low maintenance requirements due to simple design and long filter life

-

Enhances compliance with regulatory cleanliness standards such as ISO and GMP