FR1901 SMT Stencil Roll

Products

Products DETAILS

FR1901 SMT Stencil Roll

What is an SMT Stencil Roll?

An SMT stencil roll is a lint-free, highly absorbent cleaning roll used in automated stencil printers during the solder paste printing step of Surface Mount Technology (SMT). These rolls are critical for cleaning the underside of the stencil, which ensures precise and defect-free solder paste application onto printed circuit boards (PCBs).

Purpose and Function

During SMT printing, solder paste is applied through a stainless steel stencil onto the PCB. Over time, paste can accumulate or smear on the underside of the stencil. If not cleaned properly, this leads to defects such as bridging, insufficient solder, or misaligned prints.

Stencil rolls are installed in the printer and are automatically advanced and used to clean the stencil bottom using dry wiping, wet wiping (with solvent), or vacuum assistance. This cleaning helps maintain print accuracy and quality.

Construction

-

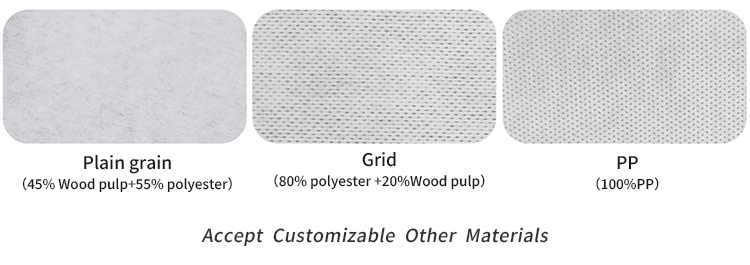

Material: Non-woven, lint-free fabric such as polyester, cellulose, or polypropylene.

-

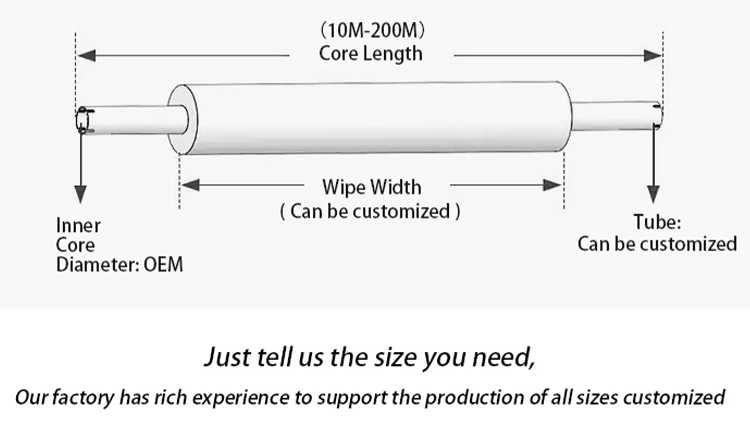

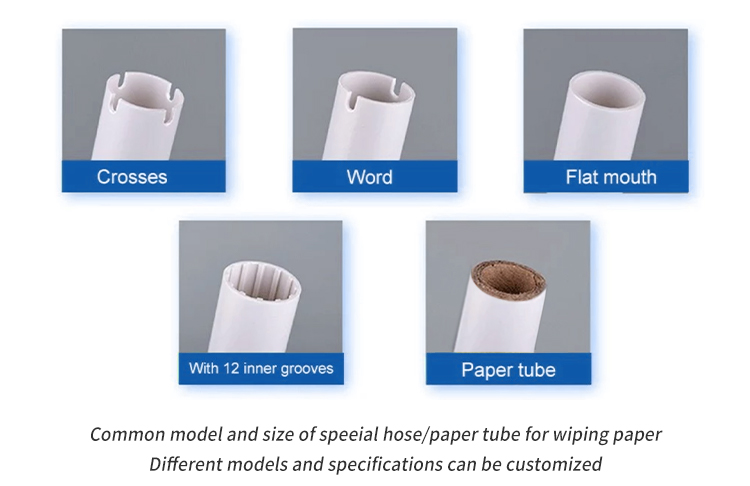

Core: Mounted on a paper or plastic tube to fit into the printer.

-

Compatibility: Can be used in dry mode or with cleaning solvents like isopropyl alcohol or specialized stencil cleaners.

-

Anti-static: Often treated to be safe for electrostatic discharge-sensitive environments.

Standard Specifications

-

Roll Width: Common widths include 265mm, 300mm, 350mm, 400mm.

-

Roll Length: Varies, usually between 5 to 30 meters.

-

Core Diameter: Typically ranges from 20mm to 38mm.

-

Printer Compatibility: Designed to fit SMT printers such as DEK, MPM, Speedline, Ekra, Yamaha, Juki, among others.

It is important to check compatibility with your specific printer model.

Benefits

-

Maintains consistent solder paste application

-

Improves print quality and alignment

-

Reduces common defects like bridging or insufficient paste

-

Lowers the need for manual cleaning

-

Works with both dry and solvent-based cleaning processes

Buying Tips

-

Match roll size and core diameter with your specific printer

-

Choose material based on cleaning method (dry, wet, vacuum)

-

Use high-absorbency material to reduce cleaning fluid consumption

-

Select anti-static rolls for sensitive electronics manufacturing