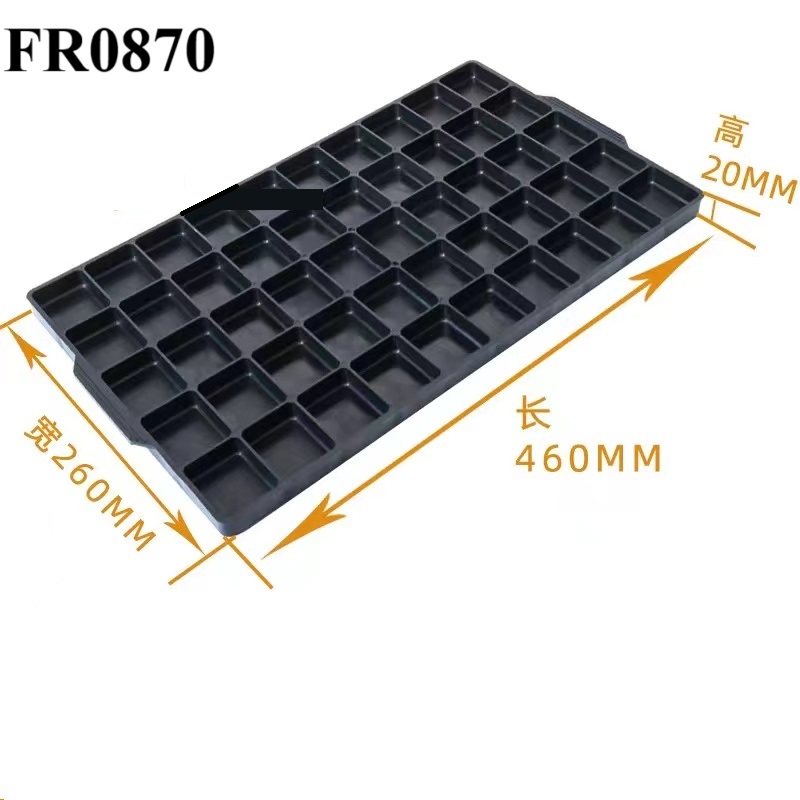

FR0870 ESD Tray With Dividers

Material: ESD Plastic

Surface Resistance: 10e4-10e7

Usage: Package and storage

Property: Conductive & Antistatic

Color: Black

External size: can be choose

Industrial Use : Electronic

Products

Products DETAILS

FR0870 ESD Tray With Dividers

ESD Tray with Dividers

An ESD Tray with Dividers is an anti-static storage and handling solution designed to safely organize and separate multiple electrostatic-sensitive components within a single tray. The integrated dividers help prevent component contact, minimize movement during handling or transport, and ensure ESD-safe organization of small parts, PCBs, or assemblies.

Key Features

-

Electrostatic Protection: Made from conductive or static-dissipative materials to prevent static build-up and discharge.

-

Integrated Dividers: Fixed or removable compartments keep items securely separated, reducing the risk of mechanical and ESD damage.

-

Efficient Organization: Ideal for sorting and transporting multiple components in assembly lines or repair stations.

-

Stackable & Space-Saving: Designed to be stackable without compromising the protection of contents.

-

Durable Material: Chemically resistant, heat-tolerant, and reusable for long-term industrial use.

Specifications (Typical)

-

Material: Conductive or dissipative polypropylene / ABS / fiberglass-reinforced plastic

-

Surface Resistivity:

-

Conductive: 10³–10⁶ ohms/sq

-

Dissipative: 10⁶–10⁹ ohms/sq

-

-

Divider Configuration: Customizable grid layout (e.g., 3×3, 4×6, etc.)

-

Tray Dimensions: Custom or standard sizes available

-

Optional Features: ESD-safe lids, handles, label holders, and cushioning foam

Applications

-

Component sorting during production or repair

-

Safe storage of ICs, PCBs, sensors, connectors, and small modules

-

ESD-compliant WIP (work-in-progress) handling

-

Inventory management in electronics manufacturing